Hydraulic press machine maintenance the recommended oil for hydraulic press machine is to be 32 and 46 anti wear hydraulic oil with oil temperature ranging from 15 to 60.

Power press machine maintenance.

The oil should be strictly filtered before it is allowed add into the tank.

The power press machine has revolutionized this process by adding force and accuracy in the operation of pressing.

Mechanical power press guarding and construction general yes no n a 1910 217 b 1 are machine components designed and secured to minimize hazards caused by breakage or release of mechanical energy i e.

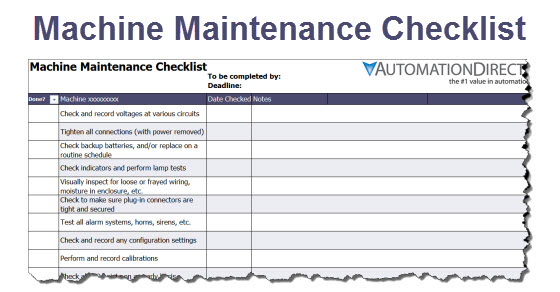

Check the main motor s lubricating situation.

1910 217 b 2 do friction brakes provided for stopping or holding a slide movement.

Check the clutch magnetic valve.

For mechanical punch press maintenance you should not only pay attention to daily maintenance but also weekly monthly and yearly maintenance.

Check the power light and emergency button.

Osha instruction std 01 12 021 std 112 21 29 cfr 1910 217 mechanical power presses clarifications 10 30 78 ansi b11 1 2001 safety requirements for mechanical power presses.

Power press machine works on the principle of reforming the metal sheet by applying the required force.

Carl jean is a service manager with greenerd press machine co p o.

Box 886 nashua nh 03060 6349 603 889 4101 ext.

While most hydraulic presses share the same core needs for maintenance it is always best to start by following the specific schedule supplied in your machine manual.

Never put off a problem for the next person to report or repair.

Check the air pressure.

Check the inching stroke.

Preventive maintenance is a small price to pay to keep your press running.