After forming the green ceramic undergoes a sintering or firing process to produce a strong final product the driving force for sintering is the reduction in surface energy of the powder particles sintering.

Production process of ceramic tiles pdf.

We will discuss all the production process methods used in the ceramic industry.

Steps in the tile manufacturing process are.

Useful for both clay and non clay compositions.

Department of commerce william m.

Porcelain tile is ceramic mosaic tile or paver tile that is made by a certain method called dry pressing.

The term ceramic forming describes the process of production of ceramic components from natural or synthetic raw materials.

Ceramic wall and floor tile manufacturing 1997 economic census manufacturing industry series 1997 issued august 1999 ec97m 3271e u s.

M tech ph d materials engineering sest uoh 2.

Ceramic tiles are economical to produce because of the raw materials used are easily available mined ceramic minerals.

Decorative wall tile is glazed tile with a thin body used for interior decoration of residential walls.

Batching is the initial step in the tile manufacturing process.

Mallett deputy secretary economics and statistics administration robert j.

The primary raw material for the tile production is clay quarts and feldspar.

The types of commercial clays used for ceramics are primarily kaolin and ball clay.

Produce ceramic and or glass particles by grinding.

Census bureau kenneth.

15 3 modeling the ceramic tile production process 381 t able 15 4 sequence dependent setup times and anticipatory flags s iljk and a iljk for the example i 1 i 2 i 3.

Manufacturing process of ceramic tiles 1.

Installations for the manufacture of ceramic products by firing in particular roofing tiles bricks refractory bricks tiles stoneware or porcelain with a production capacity exceeding 75 tonnes per day and or with a kiln capacity exceeding 4 m and with a setting density per kiln exceeding 300 kg m.

Most ceramic products are clay based and are made from a single clay or one or more clays mixed with mineral modifiers such as quartz and feldspar.

Continuous ball mill 6.

Daley secretary robert l.

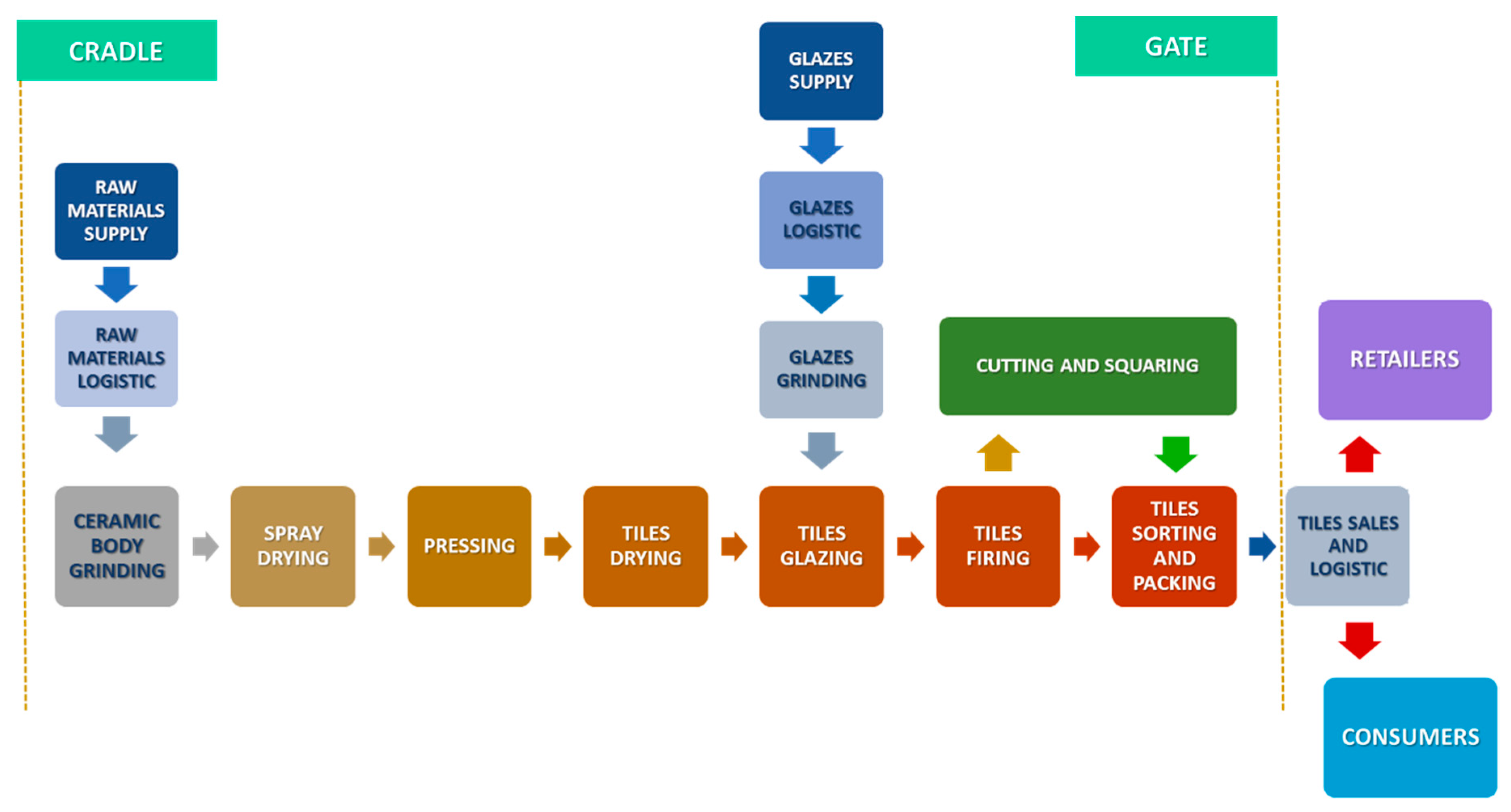

11 7 2 process description1 3 5 figure 11 7 1 presents a general process flow diagram for ceramic products.

There are different production process methods are used in the ceramic production process.

Paver tile is glazed or unglazed porcelain or natural clay tile of size 39 cm2 6 in 2 or more.

Manufacturing process of ceramic tiles vamsi krishna.